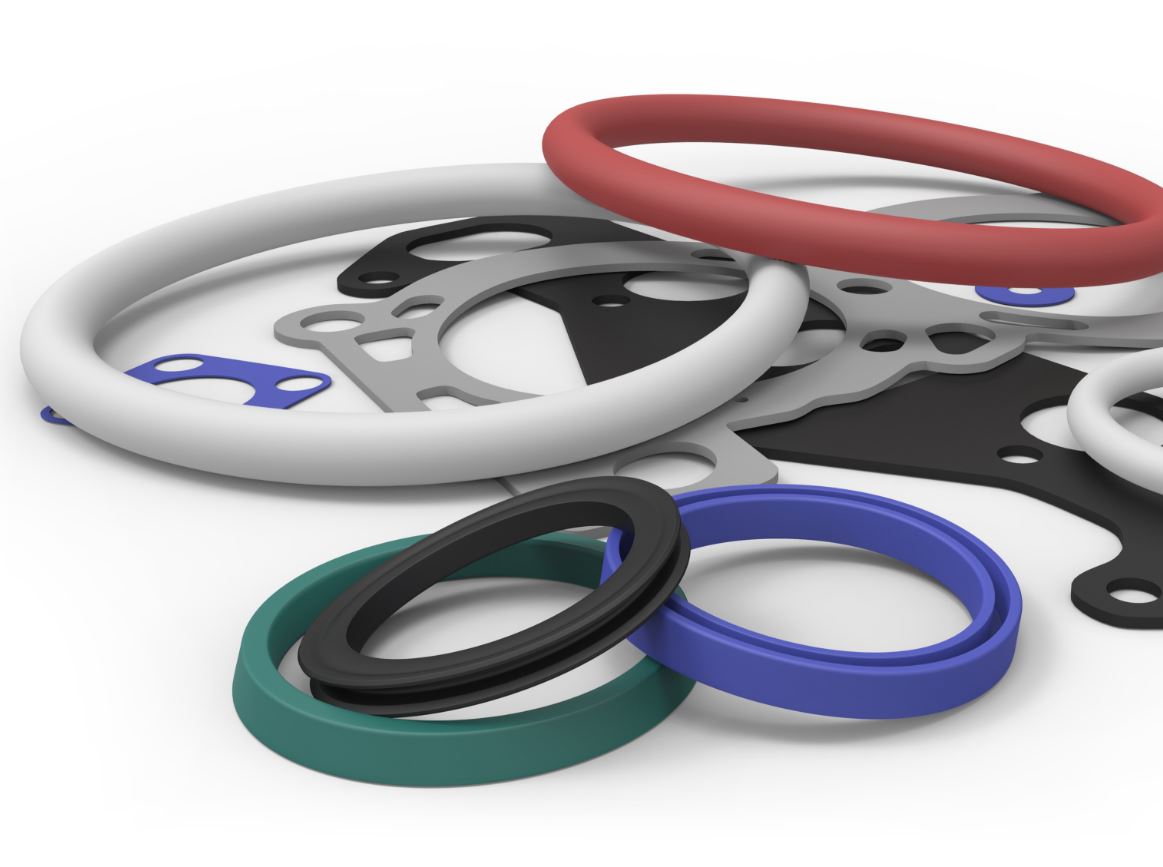

O-ring , Oil Seal, V-Ring, …

O-rings are probably the most common fluid power seals. ... O-rings seal by mechanical deformation that creates a barrier to a fluid's potential leak path between two closely mated surfaces. O-rings are typically installed in a groove that's machined or molded in one of the surfaces to be sealed.

PalmFox As a leading brand in the oil and gas industry world , guarantees its diverse and quality products. Just contact us now to consult and provide the best equipment you need. Quality and durability are the hallmarks of PalmFox brand products. Try it.

O rings are used to block a path which may otherwise allow a liquid or a gas to escape. ... When the system comes under pressure, the o ring is squeezed against the opposite wall of the groove, maintaining a perfect seal even under very high or low pressures.

Oil seals are used to protect shafts and bearings from ingress of dirt and foreign matter and egress of oil or grease. An oil seal generally consists of an outer circular metal part and an inner flexible member that does the actual sealing and is bonded to the metal part by chemical adhesive agents.

V-ring seals are unique all-rubber seals for rotary shafts.V-rings are mounted on and rotate with the shaft. The lip seals axially against a counter face, which is perpendicular to the shaft. The body has an interference fit on the shaft and holds the lip in position.V-rings are axial seals for shafts and bearings. V-rings seal axially against a counter face. The V-ring is reliable and effective against for instance dust, dirt and splashing water or oil.